CLINICAL SUPPLY MANUFACTURING ARTICLES

Sorriso's Path To Oral Biologics Dosing Is Through The Gut

Sorriso's Path To Oral Biologics Dosing Is Through The Gut

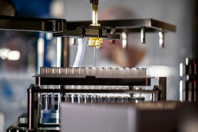

Following positive results from a Phase 1b trial, company leaders describe scaling their yeast expression and spray-drying processes as they prepare for Phase 2.

CLINICAL SUPPLY MANUFACTURING RESOURCES

-

Many small and/or early-stage companies are not aware of the need, or the possibility, of finding a CDMO that specializes in meeting their specific requirements.

-

Obtaining information and proactively mapping out your fill/finish strategy early can de-risk an investment in equipment or processes, ensuring you meet your long-term needs.

-

Optimize your speed to clinic by securing a development and aseptic fill/finish partner to support your applications with the right manufacturing equipment, communications, and SOPs.

-

CZ vial-stopper-seal combinations offer a viable solution for the challenges associated with low-temperature storage of cell therapy drug products.

-

Clinical distribution paths can be fragile for a multitude of reasons, making it critical that pharmaceutical sponsors and their partners orchestrate supply chain logistics even before site initiation.

-

Read more about trends in the biologics market that could impact the lifecycle strategies for your drug product and steps you can take around drug packaging early in development.

-

A proactive approach to packaging development can ultimately ensure a smoother launch. Explore five key considerations when selecting components for your injectable drug product.